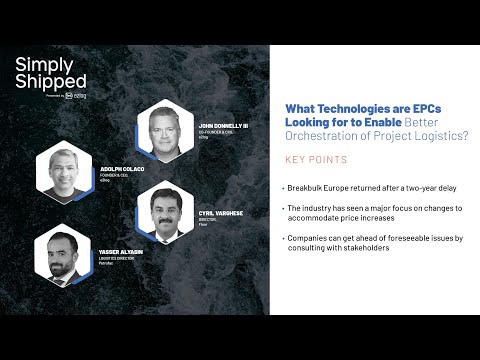

What Technologies are EPCs Looking for to Enable Better Orchestration of Project Logistics

obviously a real strong panel with years of logistics experience really excited to have you guys here with us today let's start off with the first question for uh for Cyril kind of over the last couple of years what type of supply chain disruptions have occurred um it is really a strategic shift in how people are thinking about project Logistics so um what has changed and we've all been uh hearing about disruptions in the supply chain especially in logistics over the last few years um what we see as a major shift is in the past People Like Us used to run projects for our clients where there were a lot of unit rates that Freight forwarders were comfortable in terms of fixing for a long term right we've come to realize that it's not an ideal solution because that's primarily leaving a lot of risk in terms of the commercials on the creek forwarders pretty much depriving them of the opportunity to manage projects well because they now need to focus on keeping the rate low so what we are seeing is now a strategic shift in terms of making sure that we are working on multiple formats now multi-performance may be a cost plus model in which case there would be issues in terms of how do we Define cost uh how do we identify the rights partner to work with and so on and so forth or an index linked model which also brings other challenges uh into the fold um so the whole landscape has shifted in a way uh also from a fact that a lot of our clients and the epcs would not want to fix rates when the rates are at a at an extremely high level what has not changed is the number of people who are allocated to the project so when we are looking at a format or a model which involves a lot more of Engagement with the market and adjustments of the rates and going to the market on a spot basis and so on and so forth it becomes extremely critical to have the tech piece in place just making sure that the flow of information from the uh Erp software which epcs operate or the clients have and so on and so forth into a platform which can then be distributed to the stakeholders in the market and consolidate the results and the feedback and the solutions we have and use those to further optimize the uh the shipments and the way we do business I think that's a very critical piece uh which has changed and I can only guess that the acceleration is always started and it would gain a significant Pace in the next few few years exactly yeah sir from a petrifax perspective how has things changed over the last couple of years and what's the shift in logistics uh kind of overall philosophy would you say thank you uh obviously the past couple of years were extraordinary and especially in its nature due to the pandemic and the well-known reasons globally breakdown on the supply chain increase in the freight cost high volume of uh adult out of queues or spot spot shipments Etc we as an APC like any other industry in the oil and gas as a from a client's perspective we've been hit hard by this shift in the market and the current condition of the market and therefore we had to really be agile and quick in turning looking into Solutions let's say to minimize the damage or it's more or less damage control scenario and capitalize on the opportunities that are available in the market making good out of a bad situation more or less as much as we can within the the capacity that we have as an EPC when it comes down to the logistics part of the full supply chain for an EPC contractor so what happened is we we've been let's say experiencing high volume of inquiries coming on a fast track Turn Around reacting and firefighting instead of actually as it used to be before at least do planning and as a logistics team within a supply chain for an oil and gas companies were not prepared in terms of resources for or platforms for for such a market condition and talking about platforms this has it was an eye-opener of how can we streamline our process to be always prepared and may open the door for a new strategy going forward because we don't believe that the traditional way of executing Logistics will be the same as the future going forward I think there has been a drastic change during this pandemic which is an eye-opener for all epcs in general or clients in particular for how we can orchestrate our Logistics in the future of course you will still need to manage the con the context of a logistics part of the supply chain so you don't want to grow the business to become another Freight forwarding inside a company there are freight forwarders have their jobs but we need to introduce new strategies and we need to be internally better prepared in a sense for Logistics being now on the high priority as well for all the for the supply chain in general being prepared to analyze data and have a quick turnaround out of cues or inquiries in the market that could materialize to serve still the project schedule and be more cost effective excellent thanks guys I think one of the things that's happened I guess with epcs over the last few years is that traditionally you've worked with mostly kind of fixed rate contracts and as the market shifts have happened I guess uh Cyril have you seen a trigger or any kind of Shifting in terms of uh how APC is looking at fixed rate versus spot rate pricing what's your perspective on that yeah again I I guess it would depend on who you talk to there are some epcs who are more comfortable with the lump sum environment some apcs who are more comfortable with the uh with the cost reimbursable environment in certain cases the philosophy of the Prime contract would also trickle down to the next level right in terms of how Freight forwarders are approached now from an EPC perspective two things need to be taken into account one on a fixed rate contract doesn't make sense for both parties in terms of engaging in a fixed rate contract and or is another contract format a better solution right now um what we need to take into account is the number of people who are assigned to handling Logistics that mindset is not shifted right so we now need to potentially manage a large complex project with a resource pool of maybe five people or two people depending on what is allocated to it um with a new format which means it is extremely important that the people the logistics professionals who are assigned to manage the project are managing a project are not doing clerical work and not just sending sending out inquiries and doing the bit tabs and so on and so forth right so from all these perspectives uh those changes would logically flow into the need to pull out the clerical work to start capturing more data to do a better estimation in the in the future and so on and so forth so so I guess um uh the short answer is uh the formats are changing it is still fluid we have a round table tomorrow uh to kind of discuss the changing formats and so on and so forth so we need to see how this all converges and how this becomes the sensible thing and I also need to kind of it's a little off topic but I need to link it to something else one of the discussions we're having tomorrow is in terms of the talent Gap we have in the industry right not too many people are coming into the project fake forwarding side uh to match the pace of people moving out of the space right whether these are retirements or moving to other Industries or not wanting to deal with the volatility and all hence it is all the more important to have a Tech play a significantly larger role in terms of how we manage a business irrespective of how the Contracting format would end up being understand I guess Yasser From petrified's perspective are you are you seeing a shift or is there further requirements kind of to meet the market dynamics from a technology perspective and what are you guys looking at in terms of how to improve your overall Logistics process from a tech perspective from a tech perspective or the general uh situation now in for for Logistics I think we need to keep up I think Logistics industry in general are way behind in terms of technology and the digitization and and this obviously we're behind to catch up with the market Trend in general which obviously have its own added value all or or else many industry won't be adopting or adapting a new platforms and trying to digitize their process so there there are the known added value for any digitizing in the in the process I think from an APC in particular then what we what we are maybe looking for is a a platform that can be integrated with a full EPC process so we have I mean petrofak has greatly invested in the digitization and starting obviously as an engineering and procurement construction company started start to focus starts from the engineering perspective which is a massive massive work that absorbed a lot of details and Analysis to get to a platform that serves you the the best and the the ball continues to roll down into the procurement and then eventually material management and construction so where do we fall as Logistics we follow within the supply chain at the end part of the supply chain to deliver before the material management and of course it's a crucial part and very important part because it impacts the schedule of the the site progression or the side progress schedule so we need to look at these things from an EPC lens what are we looking for we want somehow an independent platform that can also have the flexibility to be integrated with a full platform that is existent already in-house build or acquired from third party for the full cycle from the engineering all the way to the construction and this integration in terms of reporting and cost analysis data analysis collecting the data it needs to be also part of the full cycle we cannot be independent um now what we've seen we've seen so many platforms that are whether they're in-house built by Freight forwarder or they're using the uh off the shelf material which is not necessarily designed for an EPC or even the data and the information are categorized in such way that it speaks to the EPC language we have so many stakeholders internally and they're not experts in logistics they they're looking for specific information and that is sufficient for them so added to this is the live monitoring which we spend a lot of effort only internally with the with many stakeholders just to communicate What's the progress of a certain shipment so to have a Tracker that is transparent run by a third party not necessarily the same LSP platform which others usually do is I think it's it's quite beneficial as long as it meets and takes the box for the other criteria is a very important criterias like integrating with the in-house built systems for the APC overall right so like Erp systems things like that exactly perfect what's your perspective on kind of epc's face a lot of challenges internally kind of culturally to adopt new technology that Cyril and Yasser mentioned what's your perspective given your kind of experience in a logistics space on what's required for epcs to really kind of help adopt new things and new thinking true so I think one of the most fundamental objectives of any technology solution needs to work towards is making sure that it solves a problem this is fundamental technology should not be introduced just for the sake of being trendy and digitizing of things like that right and if you want to make an impact and solve a problem it's key to recognize who the stakeholders are within an organization when it comes to the execution of complex projects and what we found through this journey is that these stakeholders are well outside of supply chain as we all know supply chain is basically an internal Service Group within the organization they're serving say the project managers they're serving the project directors they're serving the customer For Whom the project is being undertaken and the key with technology is to actually make sure that you are making that technology appealable and attractive to those various stakeholders so that's fundamental so the whole concept of Building Technology around personas is critical so you may have one solution it may be let's say an end-to-end platform and it has to fundamentally do a few things number one is as the answer correctly pointed out it has to have the ability to integrate seamlessly in a non-intrusive manner with existing systems you have to do that because if there are systems for engineering if there are systems for material management if there are systems for planning those are not going to go away magically even if you bring one end-to-end solution but you have to ingest data from these different sources and push it out so that's one fundamental key but the second thing is let's say if a project manager cares about the scheduling piece of logistics then the solution needs to make sure that it caters to his or her needs in that respect if let's say a project controller cares about the cost aspect of a project then you need to make sure that the platform is delivering that so that they have the visibility into costs the accrual of costs and things like that if somebody from say Cyril or yasser's group needs to be able to go out and let's say get spot rates or have the ability to use rate contracts then the solution should solve their problem it needs to make it easier for them if let's say in the project Logistics business as an example when contracts are negotiated these are Monster contracts thousands and thousands of line items how do you make sure that the person who's approving the invoice at the end of the life cycle of these shipments are not stuck with a mountain of invoices right so how do you solve that problem so this is a fundamental approach of how you need to bring technology into a business for the right reasons with the right touch points solving the right problems and making it appealable to the right stakeholders but shift to uh the whole idea of digitalization within your companies in fact you serial on the floor side is there a big push internally for more digitalization across the business and what are you guys trying to look at in terms of some of the future projects to to get there yeah so there is a significant push in terms of digitalization which started a few years ago um so again like any uh it's a logical digitalization initiative uh one way to do it would be to do try and solve all the problems in one shot the other way to do it would be to try and solve logical problems step by step right so so we've come a long way in terms of digitalizing a lot of our internal processes and activities uh but we also take a look take cognizance of the fact that there is still a long way to go not just for us for anybody to to get to an optimal uh solution right um I think key to the whole uh concept of digitalization what we feel is uh and I I limit myself to the logistics right it kind of the digitalization impact and the need comes from from various sources right we need to have access uh to our data understand our cargo for example if uh if engineering tells me that they need to ship 200 000 Dia inches of pipes pools from point A to point B or uh 20 000 linear meters of 24 inch pipes from uh point A to point B um we need to First have the intelligence of what this means in terms of cargo right um so that doesn't happen in a constructive and uh efficient manner unless we are in the discipline of capturing the data upfront analyzing this converting that into organizational intelligence and then using that for moving forward and doing it so the estimation bit is a large focus in terms of how we do uh let's say a seamless journey into digitalization once we've done the estimation right then the execution bit is where we do we're looking forward to a lot more orchestration in terms of making sure all the all the parties are coming together and these could be internal stakeholder the silos which exist within the supply chain or the external stakeholders that you just mentioned it could also be let's say partners because now one thing which we need to keep in mind is our the projects are also getting bigger right earlier a two billion five billion dollar project was considered to be a mega project now these are 20 25 you know larger projects which which are coming to the market when you talk about these projects it is very seldom that you have a single EPC working on it so you will have a Consortium of multiple epcs working on it and multiple epcs mean multiple systems multiple ways of doing this how are you able to extract information from multiple platforms which reside in multiple formats and multiple terminologies bring them all together and and then trickle it down into a language which the people can understand and is Meaningful to them to take some action from from there so the digitalization effect I I effort uh not just in floor but in pretty much all the epcs I think this would be a continued Journey um where uh I'm hoping that the future would hold a situation where um we are able to optimize more and more what we are doing in terms of how we how we manage our business and you know culminate in a stage where we try and eliminate waste as much as we can excellent I guess yasu what is uh Petra facts perspective overall on digitalization how the market is shipped and what do you guys thinking about internally as you go forward for additional projects so try to be more Nimble in your technology kind of Pursuits um internally as I mentioned earlier we're investing greatly as petrified whether it's the in-house team interacting with also uh the other platforms developers to to digitize as much as possible from our process from engineering all the way down to the material management for again an obvious added value for any when digitizing any any process especially in this era um so um for within within Logistics as I mentioned earlier recently it's been it's highlighted the importance of logistics of course because of the increase in the Freight Market the lack of availability the impact that this could have onto the final leg of execution and this has alerted the top management from whether it's from on the client side or whether it's from internally where they want to understand more what's going on they're asking for more reporting they're asking for more information and more education precisely on the logistics of what's going on because this is obviously is is part of the supply chain but the impact of it is again it's a it's a chain so the impact goes all the way so now as I mentioned we're we're putting a lot of effort for a couple of In-House built or ARP to develop this to cater for better services or better reporting mechanisms that we as petrified can Logistics can provide for our stakeholders there is the leg also there is also a limit of how much do we want to invest in it and how much we want to develop it and of course depending on the products available in the market whether this could be an option or do we choose eventually to continue a we need to explore these options where we can custom make the reporting mechanism shifting from the manual reporting capturing data more data because we have more interested stakeholders now to provide them this information and the transparent transparently give them a visibility across the whole Logistics cycle and and this is what we are now investing our putting lots of effort internally seeing what we can develop internally categorizing what sort of information and how do we want it we want of course there is a big part talking about the operation live operations monitoring which as I mentioned earlier and also Adolf has touched on it there are from an EPC perspective there are so many stakeholders in one project you're reporting to the PD to the BM to the cost control everyone wants a specific piece of information right which we need to be able to provide them if we find in something that actually can accommodate all these requests and yet is flexible and give you an operational life monitoring you can minimize this manual interaction and manual reporting and have a standard platform that any stakeholder if he wishes to obtain any sort of information he can go immediately on that platform and and extract the information that are relevant to his task and for us of course it will streamline our our process to an end where it serves Logistics within that supply chain in particular excellent I guess back to you adopt when you think about kind of end-to-end kind of order life cycle management and what are these all these big shippers and LSPs and ebcs generally trying to do going forward there's been a lot of discussion in the market about you know abuse of tms's and visibility platforms and people are using a lot of different things talking about a lot of the same things what do you think is needed in within the ecosystem to help some of these companies to better streamline data the way yasu is referring to sure so I think one of the most fundamental things to to sort of recognize in the project Logistics space is that there are two core things happening in the process of executing projects there are many peripheral things but one is the product which needs to move from wherever it is procured to wherever it needs to be installed and commissioned for the completion of the project so that's one movement that is taking place and that's complex and all of you guys who are here have an appreciation for the complexity associated with moving that kind of big nasty ugly uh Carlo right but the other piece which is happening is the movement of data data is moving from different sources at the same time now historically this movement of data has been very very fragmented because it's either some parts of the transaction are happening in an Erp system some are happening in a material management system some may be happening in a homegrown system a lot of it is happening let's say in Freight forwarder systems and multiple forwarders are used some of it is in no system at all because let's say you're using a local custom broker or a local trucker they don't have any technology so when you start looking at the problem the problem is is around the movement of data now when you start looking at the solutions which have been in play up to this point if you look at how different companies have approached it some have approached it in terms of literally just throwing resources at it and literally filling up spreadsheets and getting data from different sources and making those spreadsheets available to the organization right project managers management Senior Management people supply chain Logistics people there's been one approach others have taken an approach to to build something homegrown to sort of solve the problem it's quite shocking how much SharePoint is used as an example to solution and do that but then there are other systems which have been built not for project Logistics so when you look at conventional transportation management systems whether these are systems which are brought to the Forefront by the traditional Erp players or whether they are Standalone transportation management systems with utmost respect I'll say this they are not built for the complexity of project Logistics and then when you look at let's say the systems which have been traditionally built on the freight forwarder side right they're built for a different purpose they are not built with project management as a perspective and as Cyril correctly pointed out today projects are getting so complex we're talking with one of the LNG project owners in North America wherein they're saying that we have this one project which has three epcs who are executing the project each EPC has their own suppliers they have their own Logistics providers how do we as the project owner bring this all together and really what they're looking at is the data coming together so therefore when you look at the solution inside I think it's important to understand firstly that there is no Silver Bullet the industry is is taking its baby steps towards moving towards that and you know these gentlemen here are pioneers in that respect whether they're recognizing the need to bring technology in and now you've got a sort of partially work around co-developing that technology so that it meets your needs there's so much of intelligence and experience say Within These two organizations no tech company or service provider in the world will ever have anything comparable so you're going to have to extract that knowledge and experience co-develop along the way and graduate to a point where that technology now comes in and caters to those needs so the fundamental message here is that you've got to invest companies have to invest to find the solution and I think when you take that kind of a collaborative approach with a technology partner right who brings in the domain expertise brings in the technology the ability to build it out and the Forward Thinking approach that's where the solutions come in so the solutions don't lie in oh let's go to that TMS which has been around for 10 years or let's not go to that let's go to that Erp which has been around for 20 years the solution's not there you have to build towards it that's exciting exciting times like I want to shift obviously being here in the Netherlands I want to talk more about sustainability and carbon emissions and things like that I want to get a sense I think from the floor perspective from Cyril and what are you guys seeing in terms of pressure to be much more environmentally sustainable with your projects and kind of overall what's your perspective on on that for the industry the industry stakeholders and as floor we also talk to through industrial to through other forums with uh with our clients and with uh competitors and with partners and so on and so forth when it comes to sustainability part everybody's talking about this but then there is at this point of time there is no concrete uniform or unified action item in terms okay this is how we are going to track record and reward what people are doing in terms of uh being sustainable we had a round table yesterday in which we discussed that at least on the container side there are some let's say Loosely defined industry standard it is not there on the brickwork side yet which is what we're trying to develop a lot of the clients or the owners are not expecting the epcs and the EP CS are not expecting the freight forwarders and Freight forwarders are not expecting Shipping Lines to report emissions and carbon footprint at this point of time but it's just a question of time before it comes right so we'll give it maybe maximum three to five years before which it becomes an industry standard that you cannot even bid for a project unless you you've given Advanced visibility on what is your scope three emission uh looking like right right now knowing that we will get to that stage and there are there are no two ways of looking at it we will get to that stage where uh Not only would it be important in terms of winning business uh it is also going to be important in terms of how you manage your business how you execute your projects because then the credits would be involved then your ratings would be involved there's a whole industry which is growing around sustainability right um so I think it is important at this point of time to take cognizance of the fact that this is the direction in which it is heading and have industry standards developed first and then once these standards are developed make sure that the solutions which are out there also incorporate and are able to extract data which are reported by The Shipping Lines uh compare it with the formula which has been developed look at what you've shipped in terms of the volumes in terms of the nautical miles traveled in terms of the fuel which the ship is consumed in terms of fuel efficiency of the engines and so on and so forth and start reporting more accurate uh carbon footprint measurements uh as we go along so so I think this is a shift which is happening I don't know if there are certainly systems available which use a preset number per trade Lane to say okay if I consider X metric and uh for so many nautical miles per teu right that is reported but but I think we are still a long way away from having a transparent system which can be relied upon in terms of uh proper meaningful reporting on carbon filter but it is coming that's right that's right and yes I guess from Petra facts perspective do you have any other thoughts on on the carbon emission subject or sustainability in general but I mean I can't add much to what Sarah has mentioned we're in the same pot more or less in a sense of what the demands are coming from the client the only thing I can add is probably working with a clean energy projects and clean energy clients one of their main kpis is tell us how much carbon footprint and emission are you going to burn to execute my clean energy project so where there are lots of lots more of emphasis and we've been we've already started working on with few Partners to to explore how we can capture this data right and provide it to our clients and it's going to be part of the kpis and parts of the requirements and soon we will see it in the rfqs where each service provider have to tell us also how we can save um on the emission and how can we provide this data and report it to us and we in return we have to report it to our client and we have our own internal kpis right now it's driven purely by our company where we have to also show our contribution of reducing the carbon footprint and the emission for executing our part as Logistics part of the supply chain the way we we're viewing a shift in the industry is that as logisticians for the longest time when we've looked at Solutions around mobilizing product equipment Etc we have typically looked at two factors one is cost and time that's really what drives most of the decisions we are getting to a point where the third parameter which is going to come in is the carbon footprint that is being created associated with that shipment and if you see what's happening with the airline industry today some of the airlines when you actually go and you look to book a ticket and you look at the route so they obviously tell you you pick your origin destination direct indirect but they start telling you now cost they tell you time and they tell you the carbon footprint so they have already moved forward in that particular industry now it can be argued that it's far simpler to calculate carbon footprint there as compared to the complexity of project Logistics but that's the future it is going to happen the trend is already started but I think when you when you look at one of the biggest challenges that companies have with their ability to report on their carbon footprint I'll let Yasser and Cyril comment on this is that the data is not in one place because as your product moves across the planet you have different providers who are involved in moving absolutely right and not everyone who is involved in that movement has the sophistication or the technology to even be able to capture that carbon footprint what happens if you're using uh a trucker in a remote part of the world where you're going to get a carbon footprint from not going to happen right so the importance of actually bringing the end-to-end transactions onto a single platform is critical because today sustainability is sort of it is I wouldn't say it's optional I think the pressure is is coming on corporations to do it there'll come a stage where it will be like what happened to compliance in our industry 25 years ago we didn't think about compliance it is just you did your business the way you did it and there came a stage where it was log jammed and if you didn't get your compliance in order you can do business right the same thing is going to happen with the carbon footprint side yeah and I think the the mindset around how do we bring everything onto one platform how do we manage our data how do we cater to the scope three that's the challenge companies are struggling with reporting their scope 3 because that is so distributed and technology is really going to be that enabler for it right I want to play it now a little bit more I know that uh the detailogue is a business has worked very closely with the EPC Community to build the platform out and make it more robust and just generally more scalable for a larger kind of Mega projects what's your perspective on that in terms of you know how you built out the platform and how is that how that could really help ebcs with larger again Mega projects that are out there sure so the way we we look at the the world of say project Logistics is that there is a certain commonality of process irrespective of which company you work with whether it's the EPC whether it's the forwarders the large forwarders or the smaller service providers who are supporting this product there's a certain degree of commonality and then there is a certain degree of variability based by company right because there's certain processes certain things which are done in certain companies so the way we've approached building the technology is that let's build it wherein it becomes common to the general process once you've understood that process and then you leave the configurability in the technology wherein you can adapt right so let's say if Flora says in our business okay these are common steps but these are unique to floor the ability to roll those into the solution so that it then fits well into what this flow is model or similarly petrol fact where they may have certain unique processes how things are done whether it's sometimes it could be as simple as a naming convention right for something so how do you build that configurability so that's how we've tried to approach the technology is build the common commonality factors allow the configurability but the key is to actually code develop along with the EPC right exactly wherein you actually come in you bring the you you have to bring a mature product you can't bring a half big product that's right so you bring a mature product but then the the maturation of that product happens when you go yeah the system has to be the the platform has to be flexible correct continues to be flexible and consistency continuity in the market is also quite important because you're collecting all of these data data you're working side by side with an EPC to develop your platform and the more legs and the more functionality your platform will have the more added value that probably would justify the dollar value against what you are investing in if it's going to be a platform you acquire from the market whether it's an in-house investment that you put on your resources to build your existing Erp or platforms to cater for this information and the flexibility as you mentioned is quite important because also every stakeholders today will we're probably looking for a different set of information that you haven't covered for so how much can you develop to cater for all of these options and configure it as you say with the within the existing platforms that the EPC are using great point and I think part of the what has to be achieved and this is what we've done is if we go back to Erp implementations and I'm not throwing any Erp under the bus okay I'm just uh I'm just and they have a very specific purpose and they do certain things really well but if you think about erps when you've implemented erps at your companies if you needed a change think about it if you needed a change you need a configuration to be done it takes weeks to get the change order approved and then it takes months to get it deployed so by the time if somebody in in yasa's team said hey I need this done as a feature if it's going to take six or nine months to deliver that it you're killing the enthusiasm of co-development within an organization so the approach that we've taken is that we do two-week releases so every two weeks we are making enhancements to the system based on the inputs or feedback that we get from an EPC now obviously every feature can't be built in two weeks but certain features can be some take a little longer time but the paths that we have taken is that if a user says hey okay this is the process you have but I need this or this is going to really help our company or this particular project you can't take nine months to deliver that you have to be able to deliver that quick so that speed of movement is one thing we've been focused on but the second piece which we also brought up is critical there are existing systems in every organization if any technology comes in and becomes too invasive into that technology or the ability to ingest data from that system or push data to that system becomes a mega ID project you're going to fail right right so you have we've taken an approach of building technology which is conceptualized around digital twinning so an Erp has its place a material management system has its place a warehouse management system has its place but you bring data from these sources through very in Easy ingestion techniques put it together bundle it in the right place and then allow the execution of transactions there's a combination of all of these approaches that's the last piece of the puzzle that continue that continues the full cycle really that's what you are looking for as an EPC and I I can't agree more the you know traditionally when you look at um the risk with disjointed systems and uh many come most companies would have systems which are specifically meant for specific purposes like you said which are connected to each other but you know in principle they are built in in isolation and they're expected to work together right the amount of money which is uh we just thrown down the drain uh by not just the epcs by pretty much everybody because okay they're not able to optimize this part and this part and this part together so that the end product is is different there are uh side because of the silo mentality I would want to optimize keep my Logistics cost minimal okay I can keep my Logistics minimal uh if I ship everything in maybe in containers or uh yeah and so on and so forth but then my construction goes across position right so so all these have to kind of uh link together in an ecosystem where at the end of the day there is somebody sitting at the top who has a p l responsibility who has a budget responsibility and they need to be able to look at the bigger picture based on the information which is collected from here here Consolidated Together made into a story or a picture and say for me I want to illustrate this because it it reduces a million dollars at the construction site so I think from all those perspectives uh uh there is a lot of value that we see in uh and having a concept that works excellent well I just want to obviously thank uh thank Yasser and Cyril and adal for taking the time today uh we are going to be probably over time producing uh some more podcasts on some of the thought leaders should be talked about today with more details I have a series of questions we didn't even get to so a big big subject to talk through and we're excited to do that again going forward soon so thanks again for joining us and we'll uh enjoy the rest of the show thank you appreciate it thank you thank you thank you thank you foreign [Music]

2023-01-10 10:40