290122 Advanced Engine Technologies BS4 to BS6 Technologies

everyone. I welcome you all for today's webinar session on Advanced Engine Technology, BS four and BSC Technologies. I am Hitesh Kumar Dave, assistant professor, mechanical engineer department, would like to introduce you to today's our presenter, Mr. Yogesh Kalia.

Yogesh Mr. Yogesh Kalia sir is nothing but currently founder, director and CTO of Medvi Center of Automotive Research. Mister Yogesh and electronic and communication engineer Electronic Engineering Technologies since in last 18 years in automobile industries. He is former employee of Boss Research Team, Bangalore and Siemens Research Center, France. ah the client for Maidvi Center of Automotive Research is nothing but renowned industries and Institute like Mahindra, Bajaj, Isar Motor and IIT Madras. Sir

has delivered lectures and training in renowned IITs, NITs, ARAI, Hyundai, NITPR, Chandigarh and many more. Some of the best brain of the industry and institute in the same domain. Now, taking much time, I will hand over the session to Mr. Yogesh Kalia sir. Yogesh sir, welcome to you. Thank you very much ah

Hitesh sir. Ah so I welcome you all to this ah session, online session. My warm greetings to all the faculty members and students who are who are currently joined. Ah online. Ah Hitesh sir screen ah slides yes sir your voice is come out but your slide is not visible currently.

Kindly change it. Slide. Okay, I will change it, sir. To the world. Yes, sir. Now, it is visible. Now, you are in a pulse light.

Yes, sir. I am in first slide. So, the session today will focus on basically Advanced Technologies in automotive engines. So I am sure you are all familiar with the diesel engine, petrol engine, CNG and ah bikes, scooters, cars, you know engines are everywhere. So I will basically explain you the technologies, the advanced technologies to, which are currently being used to, to control the engines, which is basically, we will talk about electronic control units, and, what is BS four, BS 6, and all that, I will explain you in detail today. why these technologies, you know, which we are going to learn today, which is electronic control unit, what is the reason engines are being controlled by these technologies. What is BS four,

BS six, what is emission standard? And then we will go in detail of diesel engine. Technologies which is CRDI. Then we will also discuss latest technologies of ah petrol engine, gasoline engine. And then there is another area ah after treatment. Ah which is also part of this advanced emission control and we will also discuss something in detail about open issues and in the last if there is any question ah ah we will find out some way how ah students joined our Facebook live can ask questions ah we will we will find out some way So, first of all, as a mechanical engineer or automobile engineer or electronics engineer So, engine s are around since many years. So, what is the

reason why we have to change the technology? So, something which have been running very well since years. Why we must, why we are talking about now advanced technologies and you know, this BS6 and emission reduction and so on. So, the reason is first of all, the a global focus on environment, sustainability, if you, I'm sure you are all well aware about COP twenty-six. Ah where all governments have committed to reduce ah ah, the, the emission, and ah, also we are talking about net zero, where, every country has pledged to to the global ah community that each country will make efforts to have net zero emission. and

this this is the international scenario and then based on this government ah further you know, delegate these targets to industry and automotive is the, is, is a low hanging fruit. Ah, I would say they are the first ones or they are the, you know, first ones to receive the target. So, this government ah skipped Bharat stage five and directly jumped to Bharat stage six. I will ah I will I will I will explain you what is BS six, and then there is also a lot of problem in Delhi, time and again, ah pollution is, is reaching to an acceptable levels, and we have to stop the vehicles, and also in even today, in Delhi, no ah power generate are allowed to run ah on diesel. So Supreme Court has

ah has banned ah so what I want to explain you is ah there is a there is a global effort, there is a ah level at top leadership, top level in India to reduce the emission. Ah what is coming out of this vehicles. So that is why the technology which is responsible ah to to control these parameters which actually are directly ah affecting the and performance of engine must be upgraded to to meet these government targets. That is why whatever we are talking about BS 4, BS six, this is the reason because government is making the targets ah stringent day by day. and if you can if you are in, in, if you are regularly, you know, reading the right kind of news, you will know that now government is talking about by fuel engines, ethanol, our minister wants vehicle to run on ethanol which is a bio fuel, ah generated out of ah ah sugarcane and also I think lot of focus in natural gas in specially Gujarat is is leading the charge ah in natural which is methane and we are now talking about bio CNG and another fuel which is coming up is LNG liquefied natural gas.

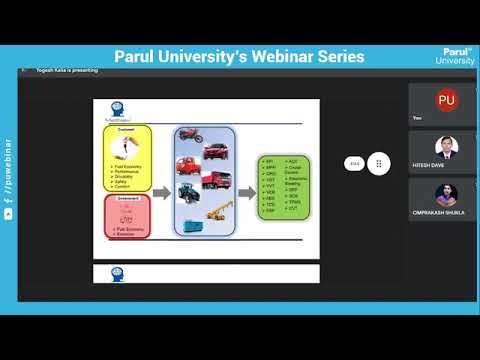

Ah this is also quite famous and ah lot of companies in Gujarat are aggressively working in this alternate fields. So ah you know all this government policies, government push and customer ah when you know I ah these apply to ah this whether it is two wheeler or passenger car or it is ah ah say load carrier, trucks, tractors ah power generators or off highway vehicles like cranes, hydronic cranes and also like combined, harvester combine. So, all of this vehicle segments are affected by these changing requirements. So, one thing is very clear, whatever mechanical systems which have been working in the past to control these engines are not good enough. So we need advanced technologies like petrol engine, electronic fuel injection, ah CRDI technology and then various ah gasoline direct injection and DPF and SEF. So there are so many

advanced technologies to to meet these stringent targets. So, we will go into the details of these technologies, technical details. Okay, so first of all, emission standards before I take you into the depth of technologies to meet Bharat stage 6. Let us

understand what is actually an initial standard and ah what what do we do? Do we mean by this? Okay, Hitesh sir, I think I'm, I'm well audible. Yes, sir, you are audible. Okay, yes sir, you are audible, continue. Right, sir, thank you. So,

emission standards, are the requirements that set specific limits. So, any vehicle, any two wheeler generator, anything which has engine when it is running. So, government has put specific limits to the amount of pollutants that can be released into the environment. So it's not that, you know, just any car can be sold and run on, on, on the, on the roads. So, government has very strict rules. So, typically, the gases which are regulated are hydrocarbons, carbon monoxide, and nitrogen oxides which is NO and NO two nox. It

is called particulate matter and then, also carbon dioxide and in some cases in gases fuels, it is also NMH which is non methane hydrocarbons and so on. What I want to say is any vehicle which is sold must meet certain ah emission criteria like you students ah or the faculty members you are aware anybody to become engineer. You must score certain grades, Certain CGPA certain percentage marks. Only then you are awarded ah Engineering ah or PhD degree. So similarly for any car or any vehicle to be sold there is a there is a similar passing criteria which is basically called emission standards. So and who prepares

it? It is it is instituted by government of India. And they are mainly based on European regulations. And they were first introduced in in two thousand and now they started with Bharat stage one on you can see on your screen on the right hand side just to ah just to ah give you some some idea that PS1 means ah there was a pollution target but it was quite relaxed and with time with the progression of time since two thousand ah BS two, BS three, BS four and slowly you can see Rao we are at PS6 and you can compare the amount of pollution just for the reference. You can compare BS

six. You are not allowed to have a lot of pollution. So, engine must have very very low emission and there are like you students, you have universities to do all this regulations. So, government has regulatory bodies and these are laboratories. it is like a examination centre for you students. So, vehicles are

tested and then emission is measured. They are driven in a particular cycle and then whatever smoke or pollution, harmful gases are coming out of the engine. goes into these machines, and, then, as per the target, they are compared if you are passed, you are given a certificate, if you are a, if you do not pass, then, you are expected to makes ah, technical changes, so that you can meet the emission targets. So, this is how it works and just to put some numbers ah on the screen. If you can if you can see ah the if you can see the If you can see the, this one, can you see? Four point 7 is, is the, is, at C plus nox, and point zero, four is the particulate matter, it is for tractor, application in India, and you can see the next target, you can see this four 7, will come to zero point four, and this. 4 will become zero point zero, two, five. So,

you can see the difference, this is, you can see nox plus HC and PM. So, which is very clear that to go from one level to the next level, there is significant reduction from for, in NoxPlus HC, it is four point seven, two, 0. 4 and particulate matter, which is actually smoke. Ah, from 0. 4

to 0. zero, two, five is ah, more than ninety percent ah reduction you can see yourself which is a lot. Okay? So now how do you, as an engineer, working on engines, how do you bring such a reduction in, in engine emission? It's a, it's a question. the answer is for diesel engine. You can see the

old technology, inline pump and rotary pump is now replaced by advanced ah ECRDI systems, common rail direct injection. Which we will learn in detail. And for petrol, we will have cargo returns, park distributor. And nowadays, replaced by NPFI and electronic fuel injection technologies and similarly brakes and other systems are also changing. So, ah the summary why as a young engineer, as a student ah studying mechanical, automobile, electronics et cetera or computer science or whatever. what is the message

is clear that in cars most of the innovation will come from electronics. So all new features, all new gadgets, all new emission control devices will be somehow controlled by electronic systems. Initial regulations, safety requirements, so you will have more and more electronic systems. So, you know it is, it is a opportunity for the universities. So, to equip your

students with this latest technology knowledge. So, that they can handle the industry requirement from the day one. my organization which is Medhavi Centre for Automotive Research written on your screens and this is our knowledge how we can combine electronics and engines and how we can meet the government's stringent emission norms is our core knowledge. We started operations in 2010. And that's

our area CRTI, GTI and so on and we work with I think Hitesh sir mentioned this to you. Ah we work with industry as well as ah ah top institutes in India I think in Gujarat we are working with IIT, Ram, IIT, RAM and also if I can recall ah I think NIT Surat as well. we have a international tie ups as well ah because this technology is ah is very very complicated. Ah the electronic

systems to four engines. So we have some ah ah technology ah partnerships, some development we do in Sweden. And ah that's how it is. Now I will come to the first technical topic where in I will explain you the CRDA Technology Diesel Engine Technology that how an electronic system based is ah fuel system. Which is actually CRDI system. How it can be used and how it works and how this technology works. Electronic,

it is also called electronic diesel control CRDI technology. So, the full form is common real direct injection, common rail because you have a it is also very important question. So, white is called common rail because this pipe, can you see, is, is a common rail, which is like a accumulator, where diesel is pressurized and stored and this pressure is regulated, I will explain you.

And these injectors, if you see carefully, are responsible to inject the diesel, this one, one, two, three. So these injectors are RS to deliver the diesel directly into the combustion chamber right on the top of the piston when the piston is moving towards TDC in compression stroke so these injectors will inject the diesel at very high. pressure. So that's why it's called common rail and direct injection. And EDC electronic diesel control because there is an electronic system ah involves which controls ah diesel system. So that's why it

is called electronic diesel control as well. It is ah I hope slow fast continue. Okay. So electronic diesel control CRTI is everywhere. You take Nissan, Micra, it is called DCI, Maruti, Swift. Diesel, Artiga, or any diesel from Maruti, you will find a word DDI BS Journal Motors, you will find TCDI, Mahindra, any vehicle you will find CR, D, E, Ford, Figo, TDCI, Tata, vehicles you will find die core and in the end you will find Hyundai vehicles with words CRDI and there are so many other words like CDI on Mercedes Benz. you will find ah

ah DDIS and D 4D on Twitter vehicles and so on. So each company may have a different ah different acronym, different word but in the end all means the same that the engine is is CRDI technology ah control where an electronic control unit is is it doing all the control work ECU, what is the work of an ECU before that let us ah I think you all know Indians very well. Ah diesel engine four stroke, suction stroke, ah air enters, compression stroke, whatever air has entered, is compressed, and when the piston is moving towards CDC, diesel is injected at high pressure. So that

diesel gets atomized and it gets mixed with air and due to high temperature and pressure. Reached due to compression, the the diesel gets ignited, that's why it is called compression ignition engine, and you will get ah sudden increase in pressure, which will give you ah talk at the flywheel end, and this is the most important, one of the most important stroke which is power stroke. And in the last stroke you have all the gases ah going out into the exhaust line or on the environment. So, something which is affecting the combustion if you look at it very carefully ah where you are getting the torque and also combustion is happening is ah if I may ask your understanding, it's basically how much diesel you inject. The diesel quantity, the pressure at which you inject the diesel and also another important aspect is the timing, the injection timing, it is also called very technically SOI which is start of injection. So, which means if

you want to control this combustion and reduce the pollution, we must control this conversion in a very very precise and accurate manner. So, we need we need ECU I will explain you. In a mechanical system, discombustion, where fuel is going is mechanically controlled, and there is a spring and there is a can lobe and so on, but in an electronic diesel control vehicle, which I will, which you know, CRDI, when the driver presses the pedal, no mechanical linkage is controlling the fuel in a mechanical system when driver is pressing the pedal, is directly controlling the fuel ah mechanically through some linkage, some levers, some springs, some camshaft. But in an electronic diesel control, this request goes to ECU. Which

also receives a lot of signals from sensors. And ah and ECU will do all the calculations. It has got softwares, algorithms, and ECU will then give command to injectors and fuel is controlled and injected into the engine. So, summary is in a

mechanical system, the combustion process or the fuel parameters are mechanically controlled but in an electronic system, the fuel parameters, the like injection timing, pressure et cetera are controlled electronically based on the signals received from the driver demand and sensors. So, this is a big difference between mechanical system and electronic diesel control. So anybody may ask what is the advantage? Advantages in a mechanical system, you can see there is no fuel, quality correction. or combustion optimization if the load is changing, if speed is changing, if environment is changing, temperatures are changing, but in an electronic diesel control, you can see the sensors. Which are sending so many signals to the, to the ECU.

like what is the altitude? Are you in Ahmedabad or are you in Manali? Is it hot? Is it summer or is it winter? So Okay, I think, did you, did you, did you, did you lost the screen? Now so we get it again. Okay, you got it again, okay. So, I was explaining you an electronic diesel control has information of of the vehicle of the environment, of the engine speed of the load through sensors. You can see

this slide. There are lot of senses like crank position, atmospheric pressure, boost pressure, fuel pressure, fuel temperature, inlet temperature, coolant temperature. So, lot of information is available to the ECU. And ECU has very very advanced software algorithms by which and data, by which ECU can then calculate and control the, output parameters like fuel, airflow, glow plugs, EGR, fuel pressure, et cetera. So, this is a CRDI system, common rail, direct injection, where sensors will give signal to ECU, and ECU will give then command to the pump and pump will generate the pressure. In the common rail, you can see on your screens. And ECU will

regulate this pressure and this pressure varies from around 250 bar. It can go up to one thousand and 6 hundred bar or in some cases it can also go up to two thousand five hundred bar. And EC will also give command to injectors based on the firing firing order. And also the injection angle and the ECU can also split the injection. So, which is called pilot injection, main injection and post injection. So, ECU has

a lot of advanced features to to control the fuel. So, this is how the ah fuel system looks like in a in a vehicle, you will, I will, I will explain you the, the, the flow diagram, this is how you will find, so, you start with the fuel tank, and there is a fuel pump, electrical fuel pump, and then fuel goes to filter number two, and this is a high pressure pump. Ah, which will, pressurize this diesel and send it to rail, you can see. this red line ah these these red lines you can see is basically high pressure ah and these yellow lines means low pressure run on one bar, two bar or maximum two and half bar and this red line means you can go up to 1600 bar And the same diesel is supplied to the injector you can see a lot of sensors and ECU will ah control these ah parameters. And you can also there is a return line, This line and there is a return from the rail, there is a return from injector and it goes back to the tank if you ah want to see this line, you can see. This is going back to the

tank and then ECU is basically is the brain of the entire engine receiving signals and then doing the control what is the advantage to the end customer is if you have a normal mechanical system based on the environment conditions no engine control will change. You have the same control button and ECU based vehicle. You have the combustion always being corrected to ah optimise level based on the senses. Okay, so that was all on the diesel. Engine, how we can meet

advanced emission norms, how we can control the combustion, and this is our Facebook page. Uh if you want more of this information, you can also like this page. Alright, so I am moving to the next technology which is also a diesel engine technology. It is a in particular ah One, it is only one slide. it is basically SCR, which is selective catalytic reduction. So, what happens in selective catalytic reduction in ah this is actually used on the, on the gases, which are coming out of engine, it is called engine out emission. And, even after

deploying the CRDA Technology, if you cannot meet the government targets, so what is next step whatever is coming out of engine, the guest is must be treated ah ah chemically ah before they are released into the environment. You can see that this is called FCR system, selective catalytic reduction and this is very important. This chemical reaction because what we are doing is we are using ah urea tank. You can see and this is a ECU and this is a dosing wall. So what it does is it's it makes the urea, it injects the urea into the exhaust line, there is a catalyst because for any chemical reaction to happen, you need a catalyst which will not participate in the chemical reaction but it, you need the catalyst to speed up the chemist chemical reaction. So, this is a

chemical reaction which is happening. Which is in the exhaust line, controlled the ECU. Okay, so here is the chemical reaction plus NO two. Okay, I will, I will just, This is a chemical reaction.

You can see nitrogen and nitrogen or ah dioxide. Ah I think I explained you, it is coming from engine out. You can see here. And then it reacts with decomposed ammonia which is NH three and ultimately they, they react and forms nitrogen and water both are not harmful. So, this is ah how an electronic control unit ah sitting in your exhaust line ah is injecting urea into the exhaust to control the emission.

Okay, then there is another technology, it is, it is an very advanced filter, DPF filter and it is, it is sitting in the exhaust line, so the job of this is to filter out the particulate matter, the smoke, and it is the, the challenge is to, there are very, very high temperatures, sometime it can go up to 700, 800 degrees -centigrade. So, the material ah must be able to withstand that. So normally we use ah ah silicon or silica carbide. SIC it is called. And ah the another challenge is ah if you use it for around 10, 000 kilometre. Or so. It gets

choked like any filter. Ah which must be cleaned. So ah there is a process called ah I think you can read on your screen. The filter there is a point number two. Filter bill

become choked or restricted and needs to be cleaned or it is called regeneration. So, there is a computer, there is an ECU which will inject diesel into the exhaust line and it will raise a raise the temperature of exhaust so that the accumulated PM can be burnt off. So, this is a process which is happening on board your vehicle and probably you will not even know that. this is how the ECU will control the ah regeneration. Okay, now I

am, I am now moving towards the petroleums, because it is not only diesel engine, which is ah, which is getting equipped with latest BS 6 technologies even. Now you will see all the two wheelers, bikes are also upgraded to a technology. It is called electronic fuel injection. Ah, where you see no

carburetor. Carburetor have been replaced by an ECU electronic control unit. So the only thing difference ah different ah between different between petrol and diesel engine is. I think you may be well aware that in petrol engine, air and fuel ah as a mixer goes into the conversion chamber. It is compressed and ignited by a spark plug. So this is a big difference. So in

digital it's only the air and mixer is ignited by compression but in gasoline engine, petrol engine, air fuel mixer goes and is ignited by spark plug. So, what an ECU must do in a in a petrol engine is patrol injuries. there is an injector, there is an injector which is injecting the fuel into intake manifold And ah the ECU will give command to the injector. is you will receive signals from lot of sensors like throttle position sensor, engine speed, oil temperature and manifold air and based on that ECU will calculate similar to diesel what is the best air fuel ratio because in petrol engines we control ah air fuel ratio ah of that mixer which goes into the combustion chamber and ah you can see in an electronic fuel injection there is no carburetor And also the spark timing ah is also controlled by ECU and in the latest technology EFI systems even the throttle ah is is also ah electronic throttle module which is ECU controlled which is called drive by wire because there is no mechanical linkage. We are actually driving through electrical wires. This is EFI

system and this is how you will find the two wheeler, your bike these days, there is an ECU sitting in the in your vehicle. There is another advanced technology called gasoline direct injection. Ah which is ah which is super advanced and ah the difference is ah in an electronic fuel injection. The

fuel is injected into the intake manifold but in the GDI I think very clear from the name itself. That gasoline which is petrol is injected directly into the combustion chamber, you can, you can see this, I think, system layout drawing, as well, you can see this. The gasoline is being directly injected into the combustion chamber and the pressure is also very high as compared to EFI. So, how it all started? I think we started with cargo raters way back in 60s or 70s or even before that and and then we switch to MPFI to my knowledge. I think India ah Maruti 800 was launched in year 2002 or so but globally it started way before that. And GDI I think it was around two thousand fifteen ah or fourteen or so. Ah first GTI vehicle was

launched in India and today you have many GDI vehicles, you have many GDI vehicles in market, Gasoline direct rejection, they are also called, they are normally turbo, also turbo petrol.

2022-09-20 10:38